Subscriptions

Tel:+86-28-8686 8787

Fax: 86-28-6890 9065

info@TOPLNG.com

TOPLNG@hotmail.com

Skype: TOPLNG

www.TOPLNG.com

Articles

How is gas stored and what are UGS facilities

|

How is gas stored and what are UGS facilities? |

| Any product has to be stored. Gas is not an exception. The underground gas storage industry is almost 100 years old. |

|

Fluctuations and peaks |

|

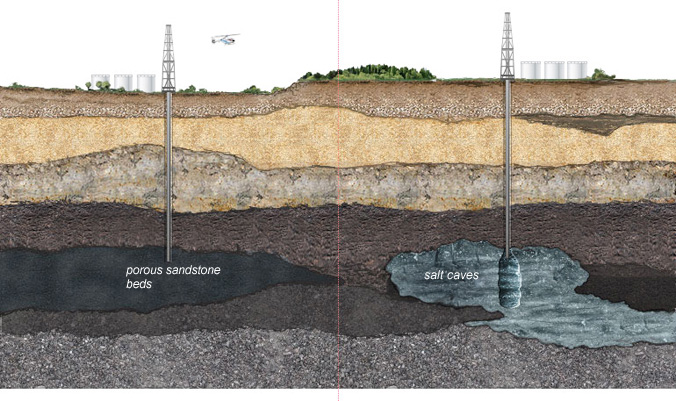

| Provident nature |

| Gas fills much greater volumes than solids or fluids. It would be therefore difficult to find impermeable reservoirs for it, if nature hadn’t built them already. Porous beds of sandstone in the Earth crust, hermetically sealed with a dome of a clay layer at the top, are natural UGS facilities. Sandstone pores can contain water, but hydrocarbons also can accumulate there. In the process of making UGS facilities in an aquifer, gas accumulating under the clay cover is displacing the water downwards. |

|

Active gas |

|

During the construction of a storage facility, a portion of gas is trapped in the reservoir to build up the required pressure. This gas is called “a buffer gas”. Its volume is about a half of the total gas injected in the storage facility. Gas, which will be later extracted from a UGS facility is called “active” or “working” gas. The Severo-Stavropolskoye UGS facility is the largest in the world. Its capacity is 43 billion cubic meters of active gas. That would be enough to meet annual demand of France or the Netherlands. The Severo-Stavropolskoye UGS facility was constructed at a depleted gas field. |

|

Self-healing caves |

|

Salt caves are ideal impermeable reservoirs. It is not difficult to build an underground salt cave, though it’s a long process. Wells are drilled in a fitting bed of rock salt. Afterwards, water is pumped into them and a cavity of the required size is washed out in the salt bed. A salt dome is not only impermeable to gas: salt is capable of “self-healing” fissures and fractures. Two storage facilities in rock salt deposits are now under construction in the Kaliningrad and Volgograd Oblasts. |

|

| How it works |

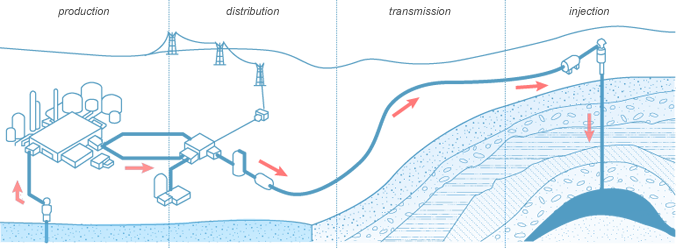

| Pumping gas is about injecting it in an artificial gas field using the parameters, specified by the process design. Gas is routed from a trunk gas pipeline to a site for removing solids, then to a gas metering station, and then to a compressor shop, where it is compressed and supplied to gas distribution stations (GDS) via headers. At a GDS, the general gas flow is divided in process lines, to which well loops are connected. Hook-up of process lines allows to measure productivity, temperature, and pressure of gas during an injection for each well. |

|

Back into the pipe |

| Extraction of gas from an underground storage facility is almost the same technological process as extraction from gas fields, but there is an essential difference: all active (commercial) gas is extracted within the period from 60 to 180 days. Flowing through the loops, it is received at gas-collecting stations, where it is gathered in a gas-collecting header. From there, gas is supplied to a separation site for the separation of produced water and solids, and then it is routed to a cleaning and drying site. Cleaned and dried gas is routed to the trunk gas pipelines. |

|

Other methods |

|

Gas can also be stored in a liquefied state. This is the most expensive of all storage options, but this solution is applicable when it is impossible to build other storage facilities near large consumers. Gazprom specialists are now reviewing the possibility of building such a storage facility outside Saint Petersburg. In addition, Russian gas industry has a method for helium storage. |

Mother CNG Station Compressor

Daughter CNG Station Compressor

Standard CNG Station Compressor

Biogas(Methane Gas) Compressor

Nitrogen Gas Compressor

CNG Dispenser

Natural Gas Dryer

China natural gas compressor