Subscriptions

Tel:+86-28-8686 8787

Fax: 86-28-6890 9065

info@TOPLNG.com

TOPLNG@hotmail.com

Skype: TOPLNG

www.TOPLNG.com

Articles

How is natural gas transported

| How is natural gas transported? | |

| After gas has been extracted from the land or sea subsurface, it needs to be delivered to consumers. The length of gas pipelines and gas distribution networks multiply exceeds the circumference of the Earth. | |

|

Before piping |

|

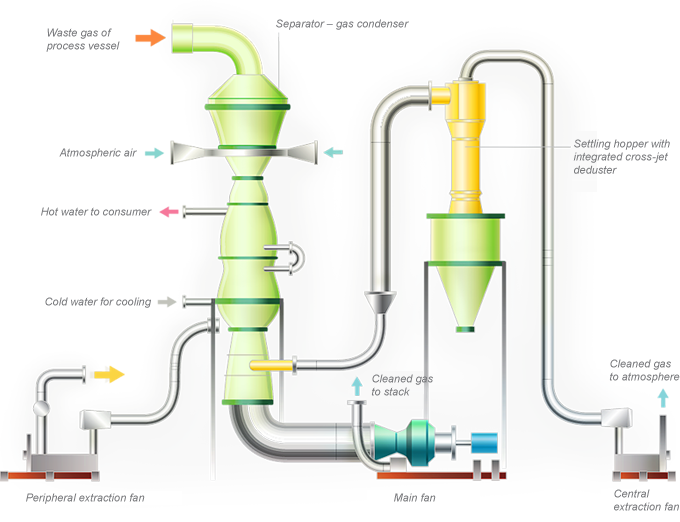

| But before gas is pumped into pipelines, it must be treated. The matter is that different admixtures that can damage the equipment come out of the well together with natural gas. Gas is cleaned from them several times: right at the well outlet, in surface separators, and in addition during the transmission and at compressor stations. | |

|

|

|

Excess substances in gas |

|

|

Gas is less needed in summer |

|

|

While daily fluctuations in gas consumption are controlled by dispatchers, seasonal fluctuations are compensated by changing operating conditions of the compressor station (CS), where gas is compressed, or by connection to the pipeline of a gas storage facility (UGS). In the process of gas compression, its temperature is increased at CS, so that gas should be cooled in order to prevent damage to the equipment. To do so, air coolers (AC) are used. Besides, gas is cooled to increase the gas pipeline throughput capacity. Natural gas occupies the smallest volume when it is in liquefied form. It can be transported as well, but in special tanks. |

|

|

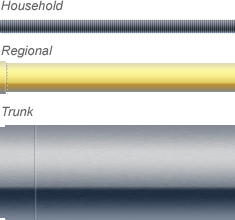

Gas is pumped at long distances using trunk gas pipelines, but for delivery of gas to end consumers, gas pipelines of a smaller diameter – gas distribution networks – are used. Depending on the consumer category, there are low-pressure (for gas supply to residential buildings), high-pressure, and medium-pressure networks designed for supplying industrial plants. |

|

Transmission process requires careful attention of an entire team of dispatchers who record pumping conditions. They take note of daily and seasonal fluctuations in gas consumption at the terminal point. |

Associated link:

Mother CNG Station Compressor

Daughter CNG Station Compressor

Standard CNG Station Compressor

Biogas(Methane Gas) Compressor

Nitrogen Gas Compressor

CNG Dispenser

Natural Gas Dryer

Natural Gas Compressor